OSMOTIC BLISTERS

Os-mo-sis (oz mo’sis) n: 1. Physical Chem a. the tendency of a fluid to pass through a semi-permeable membrane into a solution where its concentration is lower, thus equalizing the conditions on either side of the membrane b. the diffusion of fluid through membranes or porous partitions.*

*From the Random House Dictionary of the English Language.

In 1990 when a boat was hauled for a pre-purchase survey the potential buyer and both brokers often watched carefully as the hull broke the surface of the water. The brokers were mesmerized, certain that this moment would determine the outcome of the sale and their commission. The potential buyer was rapt with anticipation, fearing for the worst but hoping for a smooth blister free bottom. Being neutral with respect to the completion of the sale reduced the stress for the surveyor, but the tension always reached a crescendo when the hull bottom was fully visible. We called this the “broker’s moment”.

A sea change in perceived significance of blisters has occurred since then. Gradually, over two decades, many fiberglass boat owners and potential buyers have come to accept blisters as a normal condition with fiberglass hulls. While “the broker’s moment” has lost its drama, discussions regarding the significance of blister continue, often under or near boats hauled for survey.

The scientific data which we have reviewed over the years has generally been developed by an entity with an interest in the outcome. Resin manufacturers, repair facilities, repair tool suppliers and boat builders are among the sources of information we have reviewed. We are not aware of an independent, unbiased, scientific study of the root cause of blisters or repair method effectivity. The opinions expressed in this article come from our experience in the field, including lengthy discussions with multitudes of repairers and boat owners. Our opinions are based on examples of boats that have had various types of repairs performed due to blisters and on blistered boats which have been left un-repaired.

To begin the inspection process for blisters it is not necessary to haul the vessel. The determination of the existence of blisters is most easily achieved by a diver. During the age of the “broker’s moment”, we would often suggest having a diver inspect the bottom first, and save everyone some time and the potential buyer some money.

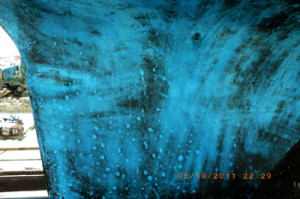

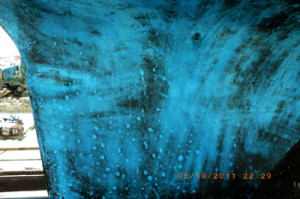

When the vessel is hauled from the water for survey, it is imperative that the hull bottom be clean to allow detection of blisters. Marine growth can hide blisters, particularly small blisters. A pressure washer can reveal blisters on a hull bottom as it were a magic wand.

After the existence of blisters is confirmed visually, probing them provides more information. Blisters can occur within an exterior coating and are often found between the anti-fouling paint and a barrier coat. Blisters can occur within any layer of laminate, they can be hard or soft, wet or dry. We characterize blisters by their size, depth, location (external coatings, below coating, within laminate etc…) number and location. We feel larger blisters are of greater concern than a large number of blisters. The depth of the blister is generally proportionate to its diameter.

Most fiberglass boats are built of polyester resin. Polyester resin contains organic components, which will dissolve in water. “Blister juice” is a sticky, brown fluid with a distinct odor. It is found in wet blisters which originate within the laminate and can be found in surface blisters, where the water has dissolved part of the polyester gelcoat.

The basic scientific premise is that water molecules diffuse through the exterior barrier (usually gelcoat) and collect in pockets below the coatings or within the laminate; thus the term “osmotic blisters”. Water then dissolves the organic components of the polyester resin and the resulting pressure pushes the coatings or laminate outward, forming the blister.

The significance of blisters is often debated among professionals. The undersigned is relatively “light” with respect to their significance. We interface regularly with several respected professionals who don’t share our opinion. The other side of the spectrum feels that blisters are cancerous and require eradication to prevent their certain, gradual and insidious growth. While we concur that no good can come of blisters and we would prefer all hulls without them, we feel that they are generally inconsequential to the ownership, operation and maintenance of a vessel.

We have never heard of a blister sinking a boat. We have not encountered multiple blisters connecting and causing large scale delamination. We are well aware of many examples of large scale delamination, however none of them have been attributed to osmotic blisters.

We have found blisters which we feel (and specify in our reports) require repair, generally they are over 3” in diameter and well into the laminate.

There are various repair options for blisters. The depth of the blisters is often considered when deciding if and how to repair them. While blisters that originate between external coatings or the gelcoat and a barrier coat are less significant structurally, the same repair options apply. A boat owner can do nothing, repair individual blisters or have “a blister job” performed on the entire hull bottom.

Repairing blisters locally consists of grinding the individual blister, filling the divot (a rare golf analogy in a boat story) and repainting. This method is suitable for local repairs and recommended for a boat bottom with a few large blisters.

A “blister job” involves removing the exterior coatings entirely, grinding away any dry fibers which remain in the area of the blisters, allowing the laminate on the hull bottom to dry, filling individual blisters and recoating the bottom. Often the bottom is coated with fiberglass material impregnated with vinylester or epoxy resins. The intent is to provide a barrier to prevent the osmosis of water, a repetition of the blister process and to return any strength removed by the removal of exterior coatings and laminates.

Many blister repairs have been successful, and in San Diego, Hull Tech is an experienced company that successfully provides this service for many boat owners. However, many boats which have had blister jobs have had the unfortunate experience of more blisters in the future. At an average “low end” cost of $225.00 per foot, ranging upward to double that amount, a blister is a significant financial commitment. As this is a labor intensive repair, it is not uncommon to have this job done in areas with less expensive labor. Mexico is an option and Baja Naval is a skilled facility in Ensenada. If you decide to have a “blister job”, choose the vendor wisely. While the value of the vessel will certainly be increased as a result, the increase will likely not be equal to the cost of the blister job.

The majority of boaters who own a boat with blisters choose to do nothing. We advise them that the blisters are not going to go away and will likely increase with time. It is uncertain at what rate they will increase or how large they will ultimately get, but they are certain to remain. The disclosure of their existence prior to the haul out for survey is the best way to diffuse their effect on a sale transaction. An allowance for blisters is almost certainly less expensive than the cost of a “blister job”.

In short it is our opinion that blisters are an unfortunate but regular occurrence on fiberglass hulls. Their significance is primarily on the day of sale and rarely significant with respect to the ownership, operation and maintenance of the vessel.

Boating and conscientious living don’t have to be mutually exclusive. There are unavoidable contradictions, the fuel burnt will contribute to greenhouse gasses and the material of the boat and supplies used will eventually be waste, but as we have raised our awareness on land, so we can at sea.

Boating and conscientious living don’t have to be mutually exclusive. There are unavoidable contradictions, the fuel burnt will contribute to greenhouse gasses and the material of the boat and supplies used will eventually be waste, but as we have raised our awareness on land, so we can at sea.

![120px-Principio_di_Archimede_galleggiamento[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/120px-Principio_di_Archimede_galleggiamento1.png) e says that the weight of the boat is reduced by its volume multiplied by the density of the fluid. If the weight of the object is less than this displaced quantity the object floats, if more, it sinks.

e says that the weight of the boat is reduced by its volume multiplied by the density of the fluid. If the weight of the object is less than this displaced quantity the object floats, if more, it sinks.

![Boat-Parade_Photo-Credit-John-Blom-Photography-1-1024x684[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/Boat-Parade_Photo-Credit-John-Blom-Photography-1-1024x6841.jpg) Highs in the 70’s and lows in the 50’s, that’s one reason we live here. Unless you leave your boat at a high elevation, you don’t need to worry about the engine block, gear case or exhaust manifold cracking. You don’t have to bother with filling the fresh water system with anti-freeze and you don’t have to haul the boat for the winter. So there are a lot of things you don’t need to do but what should you do?

Highs in the 70’s and lows in the 50’s, that’s one reason we live here. Unless you leave your boat at a high elevation, you don’t need to worry about the engine block, gear case or exhaust manifold cracking. You don’t have to bother with filling the fresh water system with anti-freeze and you don’t have to haul the boat for the winter. So there are a lot of things you don’t need to do but what should you do?

![45-FootResponseBoatHelm816x612[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/45-FootResponseBoatHelm816x6121.jpg)

![evinrude_idock_nl_120215[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/evinrude_idock_nl_1202151.jpg)

![s316283394684049153_p14_i3_w715[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/s316283394684049153_p14_i3_w7151.jpg) Legal, non lethal means includes barriers, visual and audible means and physical contact. The options include: fencing, strobe lights, horns, electric livestock fences, cattle prods, Super Soaker type squirt guns, sling shots and water soluble paint balls fired from paint ball guns.

Legal, non lethal means includes barriers, visual and audible means and physical contact. The options include: fencing, strobe lights, horns, electric livestock fences, cattle prods, Super Soaker type squirt guns, sling shots and water soluble paint balls fired from paint ball guns.