|

|

|

|

|

|

|

|

|

|

|

|

Marine Surveyors

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This article was inspired by a speech at a local yacht club. I was asked to speak about the importance of maintaining adequate boat insurance and how to maintain a boat for a good marine survey report. This article addresses the second part of the request; a prior article was written regarding the importance of maintaining suitable boat insurance.

This article follows logically from the first article as the tips contained herein will improve the condition of the vessel and will be reflected on a survey report. This article is not intended to be a comprehensive boat maintenance guideline. It gives a few specific suggestions based on our decades of experience as marine surveyors. Specifically we have specialized in insurance claims assistance and condition and valuation inspections.

A myriad of books have been written regarding boat maintenance. Most boat owners have a reasonably good idea of what needs to be done to maintain their boats. Hiring experts for specific systems such as engines, transmissions and generators is always advisable if proper maintenance is beyond your skill set.

While preparing for the speech and the articles a common theme sprang to mind. Pay attention to the subtle changes. Note conditions which are different in any way, it is your boat giving you a clue of how to save money.

Many insurance claims result from several unfortunate circumstances or the alignment of several problems, not just one event. Submersions are perhaps the most obvious example.

Submersions often result from a gradual leak that develops into a more substantial leak. There are often contributing causes including bilge pumps or their automatic switches which fail, or low battery voltage. Determine the low spot on the vessel and check it upon your arrival. Any accumulation of water higher than the norm should be dealt with immediately. Determine the source of the water and eliminate the leak. Remove the water to allow detection of any future leaks. A most honored mentor has told me repeatedly “nothing good ever comes out of water in the bilge”.

Check the function of the bilge pump and specifically check the function of the automatic switch. If you don’t know how to check the switch, now is a good time to learn. Make these checks part of your monthly maintenance program. Consider secondary bilge pumps, float switches and alternative power sources for the secondary bilge pump. All offshore cruising vessels should have a high water alarm, they are relatively simple and inexpensive to install.

Most vessels sink in their slip. While many vessels spend most of their lives in the slip, the most common causes of submersions are not associated with heavy weather or rough seas operations. Check and maintain the propeller shaft seals, the rudder ports, the deck drains and the seawater systems. Many hoses last ten years, have you considered the age of your hoses? A bilge pump cycle counter is another tool which can be useful in preventing a submersion or partial submersion event. But like any other tool it is only effective if it is used properly and any increase in the number of cycles is dealt with in a timely manner.

Through hulls and through hull valves should be inspected annually and serviced or replaced as necessary. We recommend ball valves or sea cocks and discourage the use of gate valves. Valves should be functional. Maintenance should be performed as appropriate for the valve. Pink discoloration of bronze is an indication of corrosion and any suspect through hulls should be replaced during maintenance haul outs. I have broken countless valves and several through hull assemblies in the normal course of surveying, unfortunately the failures were not the result of any superior strength, just through hulls weakened by corrosion. Often weeps, stains or salt crystal accumulation can alert the boat owner to a failing through hull or a valve. A quick visual inspection is often sufficient to discover this type of problem. Be sure to access and inspect the transom, as there are often fittings below the waterline. Look for rust stains and weeping trails for your visual clues to problems.

An owner of a vessel that recently submerged mentioned that he had noticed a problem with the culprit through hull and had made a mental note to change it at the next scheduled haulout, the haulout was unfortunately scheduled to far in the future. These are components that give the boat owner plenty of warning prior to failure but teach a hard lesson if ignored.

Heavy weather in the winter of 2009 – 2010 in the Southern California area gave rise to numerous boat insurance claims. (See Heavy Weather Boat Maintenance, a previous article). Make sure the canvas is suitable for the job you give it. Service deck drains and hatch drains as necessary. Take a look at the dock lines, chocks and cleats. These components will give you clues if they need something. Water standing on a drain, chafed dock lines, bent cleats (on the boat or more commonly the dock) are all precursors to more significant problems.

There are many simple things a boat owner can do to prevent or minimize damage from fire. Inspect the shore power cord connection and the boat’s shore power inlet. Replace any connectors which exhibit heat damage. Assure the locking ring is in place, provide strain relief and replace worn components as a matter of maintenance.

Assure that any systems or components which are added to the electrical system are installed by a qualified marine electrician. Over current protection (fuses and circuit breakers) are designed to prevent catastrophic electrical failures. Assure all devices have proper over current protection. Additionally, main AC and DC circuit breakers, and readily available battery switches are critical. Many electrical fires are foreshadowed by the definitive smell of over heated wire insulation. Turn off main circuit breakers and shut off all battery switches at the first smell.

Fire protection equipment should be maintained annually. Both fixed and portable extinguishers should be maintained per N.F.P.A. recommendations. While legal requirements only dictate the number and type of extinguishers and that the extinguishers are “serviceable”, we suggest more attention be paid to these crucial pieces of safety equipment. We have been involved with many engine room fires which were extinguished by fixed units. Countless lives have been saved by these devices but they are rarely maintained properly. There are tricks (daylight savings time) used to remember when to replace the batteries in your smoke alarms, use the same memory trick to remember to check and service the safety systems on your boat.

Other safety devices which are commonly found lacking in the maintenance department include distress signal flares, re-boarding devices, life rafts, EPIRBs, MOB devices and life preservers. Our rule for safety equipment is if you are going to bet your life on it, hedge your bet with maintenance. If it is aboard the boat when we survey it, it must be currently maintained and functional, even if it is not a legal requirement.

Machine systems, engines, transmissions and generators, are the most reliable system on the boat for providing clues about impending failures. While rust stains and water accumulation may whisper clues of impending failure elsewhere in the boat, machine systems often shout their warnings. Many of these clues do not require years of mechanical experience or skilled senses. Many of the clues simply require the operator to pay attention and be aware of the normal function of the machines.

Most engines are equipped with gauges. Changes in any of the gauges should illicit a response. A change in the idle speed, oil pressure or operating temperature is easy to notice if one simply pays attention. Many of the operators put physical marks on their gauges to allow for ease in determination of any changes. Small pieces of tape or similar markings on the face of the gauge where the needle usually resides is a simple trick to alert even the novice boat owner of a problem.

We request cold starts during our sea trials for potential buyers. Starting an engine cold is an excellent indication of its condition. Ideally an engine should start during the first turn of the crank shaft, instantly when the key switch is energized. A hard starting engine is a bad sign. Notice if your engine becomes gradually harder to start. Pay attention to the exhaust smoke opacity (density). It often changes gradually but it is visible on most boats. Observe the engine itself and properly address any fluid leaks (coolant, seawater, oil, fuel, transmission fluid) or corrosion. Pay attention to the sound the engine makes, among simple clues are belt squeals and water pump or alternator bearing noise. Know that every component on the engine that interfaces with seawater requires maintenance. The raw water pump, heat exchanger, after cooler, oil cooler, exhaust mixing elbow and even the sea strainer require maintenance.

Our experience has provided insight to a remarkable difference in failure modes between recreational and commercial vessel engines. A recreational vessel engine that has worn out is an oddity. Recreational vessel engines generally fail due to the failure of some component part coupled with a negligent response to this initial failure. Though the negligence is often a result of ignorance, it is nevertheless preventable. Conversely, commercial vessel operators pay attention to the clues from their machine systems, perhaps because their livelihood is dependent. The high temperature condition is addressed and the running temperature is returned to normal, before the catastrophic failure occurs. This is a simple and clear example of the difference maintenance makes. Commercial vessel’s engines live longer because of better, more active maintenance.

Similar clues are provided to sailors. Standing and running rigging weathers and corrodes. Roller furling mechanisms slowly become more difficult to operate. Sail covers rip and tatter before the sails themselves are exposed to the harmful effects of the sun.

Vessels powered by gasoline engines or vessels equipped with propane cooking, require specific maintenance. Gas powered boats are required to have forced ventilation in the engine space. We commonly find blower hoses disconnected and rendered ineffective. Any electrical component in a gasoline engine room or gasoline tank storage space is required by A.B.Y.C. recommendations and standards to be ignition protected. It is difficult to determine if the starter you are trying to purchase is ignition protected or not. One sure fire way is the price tag, but asking the vendor is your responsibility. We encourage gasoline boat owners to use their nose to detect for gasoline fumes upon arrival to the boat. If the boat is kind enough to provide a clue that your vessel has a gasoline leak, return the favor by paying attention. In the event of a gasoline odor, we encourage an uneducated operator to enlist professional assistance.

A well designed propane system provides the necessary equipment for testing for leaks. Open the solenoid valve and the manual valve on the tank. Shut the manual valve and allow the solenoid valve to remain open for at least several minutes. Note the pressure on the gauge at the time the manual valve is closed. Any reduction in the pressure is an indication of a leak in the system. We strongly encourage the use of propane and carbon monoxide alarms in conjunction with propane systems. Carbon monoxide alarms and gasoline fume detectors are also suggested for gasoline powered vessels particularly if they have sleeping areas.

We hope this list of suggestions supplements your existing maintenance program and provides some useful tips in maintaining the vessel to prevent damage and to improve the condition. This will not only allow for a better marine survey report, but a better boating experience. Pay attention to the subtle changes and you may prevent the catastrophic event.

In an old article entitled “Why we tap your hull” we discuss reasons that we tap on or percussion test boats. Percussion testing is used on wooden and fiberglass vessels, both single skin (solid) and composite (cored) laminates.

Many times we find small innocuous problems such as voids in the deck, but occasionally percussion testing reveals a more significant condition.

During a recent pre-purchase inspection of a 50’ luxury sportfisherman an anomaly was found during percussion testing. Initial tapping was done with a plastic/phenolic hammer (less cosmetic damage) and after an anomaly (different sound) was detected, a metal hammer (more definitive sound) was used to confirm the finding.

The area was on the starboard hull bottom and was approximately 3’ in diameter. The area sounded different than the rest of the hull bottom and subsequently we noted that it would flex with manual pressure applied.

The broker attended but neither the buyer nor seller were present during the survey. We requested that the fiberglass expert from the boat yard have a look at this problem while the vessel was hauled.

An agreement was reached between buyer and seller and a week later the potential buyer asked that we monitor the repair. The boat yard began by removing a coupon of the laminate with a hole saw. In this area the external fiberglass skin was not attached to the foam core, but the foam core was attached to the internal fiberglass skin. A few cuts later and the “never bonded” external skin was removed, leaving foam core exposed over a 3’ x 5’ rectangular area. No water was found in this area.

Three layers of a modern laminate were applied using a vacuum bag, the area was faired and several days later the hull bottom percussion tested normally.

Not all surveyors perform percussion tests. Most of the time the entire boat is not percussion tested, i.e. the upper portion of the hull sides that are inaccessible without moving a ladder slowly around the boat. We usually tap out the deck and bottom and the hull sides we can reach, but we certainly don’t tap every square inch. In this instance we performed our normal inspection and fortunately found this problem area.

I wouldn’t go so far as to use the cliché about the blind squirrel (who sometimes finds a nut), but luck is a useful tool in this surveyor’s bag.

Many of our jobs are requirements placed on boat owners. The need for an insurance policy or a loan, or a slip, etc… This story springs from a marina’s request for a survey.

Many of our jobs are requirements placed on boat owners. The need for an insurance policy or a loan, or a slip, etc… This story springs from a marina’s request for a survey.

The boat was a 40-year old 26’ fiberglass sailboat and transfer of ownership triggered the marina’s requirement for a marine survey.

During the survey, we discovered a badly corroded through hull and valve assembly and brought it to the attention of the owner. She asked if this would cause the boat to fail the survey (marine surveyor’s generally don’t give pass / fail grades). We responded that it was the marina who would decide whether the boat passed but we would suggest determining the condition of the through hull and replacing it if necessary.

The intelligent, savvy owner asked how its condition should be determined. “Start by cleaning it” I responded.

Shortly thereafter the discussion led to the methods for cleaning and possible outcomes. I gave her advice based on my experience, which she later described as a premonition.

“Be careful with your cleaning, you may create a problem”, I cautioned. She said she had emergency dowel plugs to which I responded, “Sometimes the holes are smaller than the dowels”.

Within minutes a small leak turned into a trickle as the valve stem fitting detached from the valve. While a friend of hers whittled a wooden dowel plug down to the size of a small hole, we tried numerous other implements to stop the leak. A pencil, a chopstick, a rubber glove wrapped around a pen, and finally the pointy end of a tube of caulk did the trick.

I left the boat with the client on watch and the friend dispatched to find a suitably sized cap for the now open threaded hole.

The through hull was relatively difficult to inspect and access, but once inspected, the poor condition was obvious. It certainly did not take a marine surveyor to find the deficiency, but in this case a marina’s request for a survey may have averted a minor catastrophe. The vessel had no bilge pump and the owner’s choice of cleaning implements was a paper towel, the fitting had not been far from failure.

Many times marine surveyors find expired flares and aged extinguishers, but sometimes they find something important. It doesn’t take a marine surveyor to find obvious problems like this one, but it does take a decision to look. How long since you have taken a look?

![tollroad_r900x493[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/tollroad_r900x4931.jpg) The toll road to Ensenada collapsed ab out 10 miles of north of Ensenada on December 22, 2013. An earthquake struck the area on December 19 and the road slid down the hill about three hundred feet three days later. This is the area of the road built on the side of cliffs, with the beautiful view of the ocean (and tuna pens), just south of Salsipuedes.

The toll road to Ensenada collapsed ab out 10 miles of north of Ensenada on December 22, 2013. An earthquake struck the area on December 19 and the road slid down the hill about three hundred feet three days later. This is the area of the road built on the side of cliffs, with the beautiful view of the ocean (and tuna pens), just south of Salsipuedes.

I have traveled to Ensenada three times since the slide. The road closure results in a minimal, one road detour that is easy to follow. The detour is well marked and impossible to miss. The detour is on to the “free road” and begins at the entry/exit point on the toll road know as Mission, located at La Fonda hotel and restaurant.

The detour does traverse a few switch backs on a two lane road, fairly busy with normal traffic including buses and large trucks. The detour slows the commute to Ensenada by about fifteen minutes if you are unwilling to pass the slow moving vehicles. The detour rejoins the “toll road” just south of the last toll booth (San Miguel) and all of the other parts of the road between the border and Ensenada are unchanged. You save $2.40 by missing one toll booth.

The failed section of road had been under repair for some time and the cause appears to have been reliable old gravity. The timing of the repair is not yet known.

For those who have not traveled the road in some time, there have been many changes over the past few years. ![article-2531060-1A57221200000578-98_964x569[1]](https://themarinesurveyors.com/wp-content/uploads/2016/03/article-2531060-1A57221200000578-98_964x5691.jpg) The Mexican side has a new border entry located several hundred yards west of the old entry. The crossing is much “higher tech” than the prior crossing, but still uses the red light/green light random method to determine who gets a secondary inspection. The border road on the Mexican side has been rebuilt on a raised foundation, to allow its use in rain and flooding conditions. The return to the U.S. is slightly different, requiring a little zig zag at the transition between the road along the border and the access to the actual border crossing, but it is well marked.

The Mexican side has a new border entry located several hundred yards west of the old entry. The crossing is much “higher tech” than the prior crossing, but still uses the red light/green light random method to determine who gets a secondary inspection. The border road on the Mexican side has been rebuilt on a raised foundation, to allow its use in rain and flooding conditions. The return to the U.S. is slightly different, requiring a little zig zag at the transition between the road along the border and the access to the actual border crossing, but it is well marked.

The American border crossing at San Ysidro (San Diego west) now has three options, passports, passport cards (Ready) and Sentri. The Ready lanes are for R.F.I.D. enabled cards, including passport cards. The Sentri lanes are exclusively for Sentri, Nexus and Global Entry card holders and are the fastest moving lanes. The passport lanes are for all others (with passports required) and are the slowest moving lanes.

The boating draw to Ensenada includes fishing, surfing, economically advantageous repairs and general destination cruising and exploration. Traveling in Mexico is safe and fun. My family and I have traveled all over, mostly by plane, but some by car (including a drive to Cabo) and some by boat. We understand the fears many of our friends express but we are strong advocates of facing those fears and enjoying the alternative culture that is so close and easily accessible. The narco war is mostly calmed in Baja, the risks are minimal, and from our experience they are the same as they have been for the past two decades.

There has been recent activity regarding importation permits, properly displayed hull numbers and some impounded vessels. As with any foreign country, we must follow the rules and carry the proper documents. The motivation of the traveler and the boater are often the same, adventure, new experiences and exploration of the unknown. Mexico offers all of this and if you continue south it also offers warm water!

It is vitally important for the engine(s) to be cold prior to the sea trial. Ideally the engine(s) would not have been run for several days or longer. A pre-start inspection of the external surfaces of the engine and transmission and a visual inspection of the peripheral components is performed while the engines are cold. The fluid levels are checked and any stains below the engines are noted. Among normal findings are corrosion, exhaust leaks, seawater pump leaks, oil leaks and worn hoses. If engine and transmission identification tags are visible the model and serial numbers, horsepower and gear ratio are recorded. If the maximum load/no load rpms are recorded on the identification tags that information is obtained and used during the sea trial for comparison. The same inspection is performed on the generator(s). At the time the engines are started the engine hour meter(s) reading is recorded. The cold start of the engine(s) is critical and ideally, it is an immediate start when the starter is engaged. A slow, loafing start is noted. The opacity (density) of the smoke is observed upon startup and after the engine is warmed up. If the engine has multiple control stations the engine(s) “starts” and “stops” should be used from all stations. Audible engine alarms should be available at all stations.

We always suggest that the current owner or representative operate the vessel away from and in to the dock. It is suggested that the potential buyer also test operate the vessel to assure its operation is normal and to begin learning the control systems. There is no better time to begin an education than on a sea trial and usually there is no better teacher than an owner who is intimately familiar with the vessel. During the sea trial we will test operate the engines from all control stations, the steering from all control stations and we will observe the engine gauges at all stations.

After the engines are warm the engines should be operated at wide-open throttle for several minutes. All gauges should be read at wide-open throttle and the rpms should be compared to the design specifications. The engines should be visually inspected while running at wide-open throttle. Among items, which should be noted, are the exhaust system(s), the cooling system(s); the external surfaces of the engine(s) (oil leaks or fuel leaks) and the propeller shaft(s) should be inspected at the shaft(s) seal(s).

The transmission should be shifted and observed while shifting. Differences in the operation of the transmission from the norm or from each other are important to note.

The vessel should be operated in reverse. Some vessels such as sportfishing vessels should be operated in a manner in which they will be used, such as backing down on a fish.

All the electronics that require the vessel to be moving should be tested including the autopilot (set a course, hold a course, alter the course and hold the altered course), the GPS, knotmeter (compare speed to the GPS), fathometer/fishfinder/sonar, radar etc. and other control system components such as trim tabs and fin stabilizers should be tested underway.

The generator(s) should be test operated and loaded.

The steering system should be test operated from all stations and the rudders and steering system components should be inspected.

WHEN HAULED: When the vessel is hauled it is important, if possible, to inspect the vessel while wet. A wet surface will allow detection of blisters as a dry surface will limit. It is also important to have the hull bottom cleaned. Marine growth can hide blisters that will become magically apparent as the pressure washer removes the growth. It is our job as surveyors to request that the hull bottom be cleaned, if it is not cleaned upon haul out. It is our client’s responsibility to authorize the cleaning and the pay for the cleaning. It is most helpful if this necessity has been discussed prior to the point the vessel was hauled out, preferably when the survey is being scheduled.

Sailboats:

Assure the communication is made with the current owner’s/seller’s representative so that all sailing system components, which you would like to test, are available prior to the sea trial. Raise all sails that you desire to inspect thoroughly. Raise the sails yourself, including rolling out and furling any furling systems. Check out the various hardware, sail to several different points of sail, tack, and gybe at least once.Operate the vessel with the autopilot under sail, set a course, hold a course, alter the course and hold the altered course.

Inspect the leads of the various running-rigging components and take the helm during the sail. Try to plan the sea trial during the time day likely to have wind and pray for wind.

Pre-purchase tips for potential buyer:

Ask for the history of the vessel, including the previous owners, experience of the vessel geographically, significant events in the vessel’s history (submersions, fires, collisions, hard groundings, fires etc.), the age of significant components such as engines, transmissions, generators, exterior paint/gelcoat, teak decks, standing rigging, sails. Ask for disclosure statement including all known problems with the vessel’s hull structure, mechanical systems, electrical and electronic systems, tankage etc. Ask for the history of any blisters on the vessel and age of the anti-fouling paint. If major work has been performed, ask for documentation. Ask to see any old Marine Surveys.

If items are seen aboard during an inspection and there is any question that they are part of the sales transaction, discuss them with the seller’s representative.

If there have been any items recently repaired or replaced, obtain paperwork and analyze the warranty. It is best to obtain this information in writing if possible. The “disclosure” of problems during boat transactions is usually not well documented and a record of these important communications can be valuable. is best to obtain this information in writing if possible. The “disclosure” of problems during boat transactions is usually not well documented and a record of these important communications can be valuable.

This article was edited on March 1, 2016.

Spend time at a boat yard and you will be sure to hear the tap, tap, tap of a marine surveyor. “What are you looking for?” is a question I hear with regularity. At a boat show recently I heard a broker complain about a surveyor who “showed up with a small hammer and tapped everywhere.” Here is why I do it.

Tapping, or percussion testing, is an extremely useful non-destructive inspection technique. Tapping is not limited to boat yards; it is used throughout the world and in many different fields. It is included in the inspection process of stealth technology planes and space shuttles. It provides information that is not available visually and usually causes no damage, except for perhaps a small localized loss of bottom paint.

Its primary use in a boat yard is determining the condition of fiberglass laminates. It is also useful with wood and other construction materials. In fiberglass or composite boats, tapping allows detection of delamination. Fiberglass boats and their component parts, are made of several layers of lamination. Gelcoat, coring and fiberglass material with resin are among the most common types of laminates. A separation or “disbond” can occur at any level. Percussion testing allows detection of separation between the gelcoat and the first fiberglass laminate (skin coat). It can also detect delamination within any of the layers of the fiberglass, including delamination caused by osmosis (blisters) and disbanding of the layers adjacent to the core.

The vast majority of boats are manufactured with a cored deck. Hulls, stringers and other parts may also be cored. Coring is usually balsa, foam or plywood, sandwiched between layers of fiberglass. The fiberglass encasement on either side of the deck coring can delaminate. Thus, percussion testing both the top and bottom of the deck, where accessible, is a useful inspection technique. Fiberglass bulkheads are usually tabbed (fiberglass taped) to the hull sides. Tapping the fiberglass tabbing can determine if the tabbing is properly attached. Occasionally the tabbing does not bond (usually to the plywood bulkheads and I have seen vessels in which the fiberglass tabbing attachments (secondary bonds) were never well made. On a few occasions, this has left virtually all of the bulkheads “adrift” and grossly weakened the hull structure. Properly made tabbing can become detached due to an external force from impact, heavy weather operation or even over tensioning a sailboat’s rigging (usually a backstay).

In vessels that use organic coring material, and there are many, the most type is balsa or plywood. This wooden coring can deteriorate (fungus deterioration or dry/wet rot) and the deteriorated coring can often be detected by tapping. A properly made deck cored with balsa sounds solid and sharp when tapped; if the balsa is deteriorated the same deck sounds soft or dull. Deteriorated coring can also be detected by tapping stringers and transoms, particularly on smaller boats.

Tapping wood boats or wooden components also allow detection of deterioration. Bulkheads are often constructed of plywood which is covered with fiberglass, upholstery or carpet; tapping can reveal secrets that even the owner was unaware of. Occasionally when tapping deteriorated wood, this inspection technique becomes destructive.

Many of the things detected by tapping are minimal including “voids”. Voids are air bubbles trapped just below the gelcoat or skin coat. Tapping a void is distinguishable by the higher pitch. The area around the void will have a lower report than the thin skinned void. The voids are cosmetic and a nuisance occasionally but are rarely ever significant structurally.

The tapping can be done with virtually anything. Depending on the material and thickness of the component which is being tapped variances can be found using a finger nail, edge of a coin, butt of a screw driver or of course the preferred tool, a hammer.

Hammers can be made of bronze, steel, plastic or any hard material. As long as an audible report is made when the device taps the component being inspected. The difference in the sound made is what the surveyor is listening for. I have found metallic hammers give the most discernible reports, but I primarily use plastic hammers above the waterline. If an audible difference is determined I will also tap in the area a second time using a small metal hammer.

Percussion testing should be non-destructive. Occasionally voids will open, paint will flake and small hammer marks are accidentally made. I attempt to leave no indication of my survey and surveyors should be aware of any damage being caused by their percussion testing. One fateful survey began with a hammer becoming lodged in a rotten wooden boat. It was the first tap of that area of the boat and the last tap of that day with a hammer. I kept tapping, but used my finger.

While percussion testing is an excellent use of a non-destructive inspection technique it is but one of many inspection techniques, which are used in the process determining the condition of a vessel. Along with percussion testing many other methods are used in assessing the condition of a laminate. Flexing under foot, visual discoloration or cracks, indentations, crackling sounds when stepped on, concave or convex areas, discoloration are other signs of potential problems. Moisture meters can be used to help assess the condition of laminates and, when necessary, destructive techniques can be employed.

This article was edited on March 1, 2016.

It’s a familiar story around our office; the client has already purchased a vessel and now finds themselves in need of a survey. Occasionally, the client did not know the trade of marine surveying existed; more often they decided to save the expense of the marine survey when buying the vessel. Most often the boat fits on a trailer and will be stored in the driveway. The surprise comes when they decide to insure the vessel (or get a loan or a slip).

Many insurance carriers require a marine survey before binding the coverage. Underwriting criteria differs, but can include length, age or value of the vessel. Whatever their criteria, insurance underwriting often dictates the need for a marine survey. That is when we get the call.

Client, “My name is Mark H., and my insurance company needs me to get a marine survey on my vessel. I bought the vessel about two months ago and have been fixing it up; it’s in great shape”.

Surveyor, “O.K. Mark, we have just the product for you, a slightly less extensive inspection and shorter report, designed for owners seeking insurance. Price is slightly less than the survey we offer buyers, on your 25’ vessel that will save you $100.00”.

“Great, let’s schedule the survey for tomorrow morning so I can have my insurance in place for this weekend” Mark replies.

Everything is smooth so far and then I arrive at the vessel. Within moments I notice a group of unusual stress cracks on the starboard forward chine. After a brief introduction I begin the survey and point out the unusual stress cracks. Mark explains “I bought the vessel from a friend and went fishing on it several times, I am sure it is in good condition”.

Thirty minutes later I feel like the doctor bringing bad news to the patient’s family, in the waiting room. “Well Mark, I have some bad news. I found the cause of the stress cracks on the chine, the wood coring for the stringers is deteriorated”.

“That sounds bad, is it repairable?” Mark asked.

“It’s repairable, but it is going to require some time and effort or money; and you won’t be going fishing this weekend”.

This is a true story and though perhaps more drastic than the average findings, it is illustrative of a typical situation. Mark saved about $100.00 on the cost of the survey our company would have performed for him by being an owner versus a buyer. He chose to effect the repairs himself, the cost of material alone was significantly more than his savings, in fact the materials cost was equal to the cost of a pre-purchase survey. Mark’s labor cost was 16 hours, spread over three weekends. In Mark’s case that was equivalent to four rounds of golf, eight surf sessions or twelve long bike rides with the wife and children.

Many boat owners are not as fortunate as Mark, and don’t possess the skills to repair deteriorated stringers or other significant problems and must hire professionals at labor rates often approaching $100.00 per hour.

Mark just purchased a new boat; he hired us to inspect it before he wrote the check. He said “this is the best insurance I can buy!”

Marine surveyors provide benefits to boat buyers, not just buyers of large yachts. Surveys are often required for insurance and finance and lately by many marinas. Mark’s case illustrates a common misconception that a survey isn’t necessary. Check with your insurance company, lender or marina to see if you will need a marine survey, even if you don’t want one. Carefully consider the benefits of a survey against the expense, before you buy the boat and then choose your surveyor wisely.

This article was edited on March 1, 2015.

Marine surveying is a niche trade. Marine surveyors inspect ships, cargo, boats and yachts. Christian & Company works primarily on boats and yachts. We assist with damage claims, we provide litigation support and we perform the type of survey with which most boaters are familiar – condition and valuation inspections (C & V). With respect to C & V’s, one of the most common questions we field is “how do I prepare for the survey?”

The preparation varies slightly for pre-purchase surveys versus insurance/financial surveys, but in general it is the same. Maintain the boat. If you are interested in further specifics, continue reading.

Prior to survey, the vessel should be open, all storage compartments should be unlocked and all spaces should be accessible. Boats being surveyed for purchase should be emptied and cleaned. Boats being surveyed for other purposes should be de-cluttered, and cabins and lockers should not be stuffed full of personal effects, sports equipment, spare parts or sails. Alternatively, providing the surveyor with assistance in unpacking the lazarette or the quarter berth, which hold ten years of swap meet acquired treasures is not only appreciated, but adds to efficiency. In extreme cases, areas are not accessible (hoarders can live on boats too) and the result is incomplete inspections.

It is important that vessels being surveyed for purchase have easily accessible storage spaces and bilge; fifteen deteriorated life jackets provide no benefit. We also suggest that sellers have their vessels cleaned both internally and externally. Many vessels are purchased by couples and at least one partner will notice the dull finish, dirty floor and waste odor. Ventilate the boat, eliminate the mould and don’t leave the exterior cushions soaking wet.

Ideally the engines have been maintained and function normally. At a minimum the engines should start, the engine controls should function and the steering wheel should turn the rudder.

Common mechanical short comings are hard starting engines, high exhaust smoke opacity, cooling system problems noted by spiking temperatures at high rpms and inability to obtain designed wide open throttle rpms. Many conditions leading to these problems can be avoided with normal and prudent maintenance and since the buyer or insurance company will likely require these deficiencies to be addressed, you may as well do it before the survey.

Other mechanical problems which are commonly found during surveys are leaking propeller shaft seals, improperly functional or improperly maintained steering systems, stiff, broken or abandoned controls and inoperative bilge pumps. Addressing any and all of these deficiencies prior to the inspection will result in a cleaner report and a better chance for the sale, insuring or finance of the boat.

Dead, dry or cracked batteries are a huge problem during a survey. Not only are the condition of the batteries and the charging system brought into question, but inadequate DC power can lead to numerous other electrical problems and the general inability to test components. Batteries should be tested, serviced and charged prior to the survey. A boat that has half of the lights not functioning does not reflect well on the owner and the maintenance program. Take an hour and change the bulbs before the survey.

Service any problems with significant electronics prior to the survey or disclose the problem in advance. We have witnessed the enthusiasm drain from many a potential buyer after the fifth or sixth time when they were told “well it worked last time”.

By far, the most common findings on surveys are deficiencies in the legal carriage items and safety equipment. Buy some new flares, service or replace the fire extinguishers and make sure that the navigational lights and horn are functional. Not only are these legal requirements, they are absolutely necessary for the safe operation of a vessel. O.K., flares may only be necessary in an emergency, but they are relatively inexpensive.

For pre-purchase surveys, we strongly encourage owners to perform “pre-trials”. A week or two prior to the survey and the sea trial, take the boat for a test run and check for all the things mentioned. Go to the electrical distribution panel, energize and test the components, heat the water and make some ice, put the ice in a glass, pour yourself a drink and congratulate yourself for being a prudent owner. You will inevitably have found a component or two that requires service or replacement and you will now have time to address these issues or minimally disclose them and diffuse the power of surprise that can detrimentally affect the sale of the vessel.

On larger vessels with more complicated systems, the same concept applies to the systems. The tender should be test operated, the batteries should be charged and the fuel replaced. Perhaps the carburetor requires service if the outboard engine was not run dry when it was last used.

Service the water maker and make it ready to use or check with the broker or potential buyer to see if the water maker is of concern.

Ask the broker about the buyer’s interests and potential usage of the vessel. If she is a fisherman, prove the bait system. If he is a fisherman, stock the refrigerator.

This article was edited on February 29, 2016.

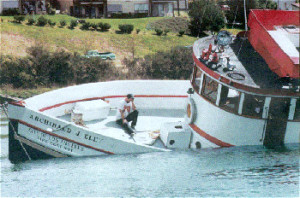

Part of our normal business is assisting with insurance claims, many of which result from accidents. There are ”normal accidents”, like groundings, collisions, allisions (when only one boat is moving), fires, trailering accidents and then there are the freak accidents. This is about one of the latter, an extremely unusual boating accident.

I will begin by relieving your anxiety: nobody died! There were two men aboard at the time, one had almost no injuries (call me lucky) and the other was bruised but recovered quickly. Fortunately no one was under the boat.

The story begins with a client asking us to survey a boat in San Carlos, Mexico. This is a coastal city on the northeast side of the Sea of Cortez, on the mainland, near the city of Guymas. The client had a 55’ Californian power boat and needed a marine survey for insurance renewal purposes. The author traveled to the boat and accomplished the survey, it had been hauled by an amazing hydraulic trailer, on a boat ramp, normally used for much smaller boats with much smaller trailers. Prior to my arrival, it had been blocked beside the boat ramp in a dirt lot.

While I was surveying the power boat, the owner of a 38’ Globe, full keeled cruising sailboat, which was blocked beside the powerboat, asked if I would be able to survey his boat as well. He also required a marine survey for insurance. He was planning a world cruise and was applying for insurance through Lloyds of London. I accepted the job as it was clearly a win – win opportunity for all.

After completing the inspection of the powerboat, I began the inspection of the sailboat. I began on the bottom; bottom painting was in progress. After inspecting the bottom, we climbed a ladder and inspected the deck. The owner was with me and after inspecting the deck, I followed him into the cabin, that’s when the accident occurred.

I was still on the steps in the companionway, leading from the deck down into the saloon. The owner was on the starboard side of the saloon when I felt a shudder and then it happened….the boat fell.

It fell to port. It landed hard on its port side and the masts wrapped over the adjacent powerboat. My client fell to the port side of the saloon and all matter of debris rained down upon him. I was very lucky and steadied myself in the companionway, watching him become buried and then emerge from all of the large and small bits which had been dumped on top of him. My first concern was his safety and health. He later said he felt like he just played a game of tackle football, but he had no broken bones, no concussion, and no serious injury. Our concern then was the bottom painters, and we quickly scrambled out to check. Everyone was unharmed.

The painters had moved the jack stands improperly and the boat shifted, allowing the jack stands to slide up the hull and the boat to crash down.

That evening I received two phone calls in my hotel room. One from each boat’s insurance company, asking if I could assist with the damage claims. I accepted the first assignment, but was unable to help the second one professionally, due to a potential conflict of interest. The adjuster was a friend and long time client. She teased me for years about going down to Mexico and knocking a boat over to get work.

The call to the powerboat owner was interesting, I told him I had some good news and some bad news. The good news was the boat was in good shape; the bad news was that there were two aluminum masts wrapped over the top of it.

The sailboat was repaired and was one of the only boats I have been involved with that was “re-gelcoated” on one entire side. Gelcoat goes on smooth in a mold, but is very rough when applied externally like paint. It required several hundred labor hours to make it shiny again, but shiny it was and the world cruise was accomplished.

The lesson I learned was the importance of safety in the workplace and boatyard. There is a proper way to block and secure boats while hauled. There are dangers and we should all be aware of them, not just falling boats, but slippery surfaces, trip hazards, electricity, etc… The accident happened in Mexico at a very rudimentary haulout and blocking area, no pavement or concrete, no travel lift and no chains in use between jack stands, but even in the technologically advanced area of Southern California, boats fall and accidents happen.

This article was edited on February 29, 2016.

WE’RE ON PAWN STARS

The caller identified herself and asked if I would be interested in appraising a one man submarine. Initially, I declined, as this is outside of my area of expertise. She then said she was with the reality television show “Pawn Stars” and could I help her locate an expert.

I told my kids about the call and they quickly became excited. They knew the show. I could not find a submarine expert, and with my kids’ encouragement, I called back to the production company and told them I would accept the assignment. As valuations of unusual vessels are not unusual, I was confident I could do the job but I insisted that I could not comment on the safety or function of the submarine. They engaged my services and explained the rules of reality television, i.e. no pay!

I told the kids I had been hired, but “hiring” in this case, did not include any pay. I was extremely pleased with my children’s universal rejecting the idea of working for free. However, their excitement had become contagious and I had caught the reality television bug. This reality television show, with which I had little exposure, had peaked my curiosity and I was scheduled to appear.

The show is based on a pawn shop in Las Vegas. It is run by three generations of men and they are the “stars”, along with a comic foil nick named Chumlee. The show has a very large following as it utilizes interesting historical facts and hires various experts to explain and value a myriad of items that are being pawned.

My mother was traveling from Florida to Las Vegas where the show is filmed, and we scheduled the shoot to coincide with that trip. My 10 year old daughter and I arrived at the World Famous Gold & Silver Pawn Shop bright and early. The production company had provided scant details about the submarine, most of which proved erroneous. I prepared as well as possible, inspected the submarine and was ready to shoot. It started raining. The shoot was delayed.

After inspecting the submarine I was able to obtain valid information and perform a real appraisal. The shoot was rescheduled and completed.

The premier of the show was on Monday, April 11th 2011. The episode involving the submarine is entitled “Sub For Sale” and can be seen on the History Channel’s web site, reruns on the history channel, syndicated on other channels or pay per view.

One of the themes of Pawn Stars is “you never know what’s going to walk through that door” and the same holds true at Christian & Company Marine Surveyors.

This article was edited on February 26, 2016.

On a recent rainy winter day I surveyed two boats. I had the pleasure to meet two nice, intelligent and experienced boat owners. At the end of the day, I decided to tell this story.

Both vessels were fiberglass power vessels built in Taiwan. Both vessels were equipped with two diesel engines that were manufactured in America. Both of the clients were knowledgeable and active boaters.

On this particular day a winter storm was just passing through. As I drove to the first boat, at a nice San Diego yacht club there were short sporadic rain showers. The client met me at the gate to the club, welcomed me aboard and turned on the electric heater, which was part of the climate control system aboard the vessel.

The vessel was a relatively new, luxury motor vessel in excellent cosmetic condition. My client was the son of the original buyer who was reportedly advancing in age and using the vessel infrequently. The client who was my age (late forties) had grown up boating with an extensive sailing history.

The survey went as anticipated until I entered the engine room. The starboard engine’s after cooler (a device that cools the combustion air between the turbocharger and the cylinders in the engine) exhibited moderate corrosion. It was mounted inboard, between the engines and was easy to see and access. A metal support for the starboard engine’s exhaust tube was disconnected. These findings, while significant, were not remarkable.

As I worked my way about the engine room, in my normal, linear fashion, I came across a substantial deficiency. Outboard of the port engine, in a location that was difficult to access, I noted an accumulation of debris in the bilge. Looking up from the debris I saw a severely corroded after cooler. The condition had no doubt continued for an extended period of time and had advanced to a critical stage.

While discussing the findings with the client, he asked if it was safe to drive the vessel to the boat yard. I responded that if the engine was starting and running normally, it was unlikely that a short trip to the boat yard would cause significantly more damage. He stated that the engine was not starting normally and had not been starting normally for some time. He said he had had a mechanic aboard, and the problem had been diagnosed as a malfunction of the pre-heating system of the engine. He subsequently explained that the mechanic was actually servicing another vessel on the dock and had only come aboard briefly as a favor. The client had obtained free advice and it had been worth every penny of it.

At the end of the survey the sun had come out, the showers had stopped and we had begun to right the course on the maintenance of the engines on this nice boat.

I got in the truck and headed south for the second job of the day. Upon arrival at a boat yard in Ensenada I found the vessel hauled and the owner aboard. His diesel heater was already on, providing comfort inside and a welcome reprieve from the cold drizzle which began shortly after my arrival. This vessel was significantly older than the first, not as pretty, modern or expensive. The owner was a live aboard and had worked most of his life in mechanical jobs, mostly for the railroad.

He had many plans for the vessel and many projects which were already accomplished.

Upon entering the engine room I noticed that the engines looked their age, with minor surface rust, and failing, dull paint. With the surveyor’s eye I noticed something different with the peripheral components. There were many new hoses and hose clamps. The end caps for the heat exchangers were clean, unpainted and free of any salt crystal accumulation about their apparently new gaskets. The water pumps were also clean and exhibited no stains, weeps or corrosion.

The survey went as anticipated and had the usual number and type of findings. During the survey the sun caught up with me and we turned off the diesel heater.

The lesson from this day and these two vessels is not new. It is that maintenance is important, can be done in many different manners, and requires periodic assessment. In the first case the client was intelligent and experienced, but was relatively new to power boats, large diesel engines and to this vessel in particular. The original owner of this relatively new vessel was no longer active in its maintenance and service regimen was inadequate.

Routine maintenance of diesel engines includes replacement of sacrificial zinc anodes in many of the components. Heat exchangers, after coolers and oil coolers are often fitted with sacrificial anodes and anodes require periodic replacement. As a rule, any seawater component on an engine will require maintenance. Beginning at the through hull and its valve, the sea strainer, sea water pump, coolers and ultimately the exhaust mixing elbow and exhaust system components all need attention.

Another lesson which the first vessel reinforced was to pay attention to changes in your vessel. In this case the port engine had become hard to start and a proper inspection and diagnoses had not been accomplished. Hopefully the damage was not extensive or expensive, but it is certain that the sooner the problem is addressed the greater the chance to reduce the repair expense and inconvenience.

The lesson from the second vessel was that there are many ways to maintain a boat. A trained mechanic can be hired to perform inspections and service on routine intervals or owners can learn how and maintain the mechanical systems themselves.

On the drive back home the rain was gone and a huge, full and vibrant rainbow came out.

I felt that the surveys were successful and though we found no pot of gold, we did persevere through the storm to continue cruising in the sunshine.

If the second largest purchase you ever decide to make floats… keep reading. Large yacht owners (and an increasing number of small boat owners) know an investment in a marine survey is worth while. Hire a marine surveyor to inspect the vessel prior to purchase but don’t simply “go through the motions”. Hire a good marine surveyor.

If you trust your broker then trust your broker’s selection of a marine surveyor. You are risking a lot more based on your choice of brokers than you are on your choice of marine surveyors. But, don’t trust the broker blindly, ask questions about your options, educate yourself, it is your decision. Ask the broker if they feel the surveyor is the best surveyor available, one that will represent your interests exclusively and rigorously. If the broker has a list of marine surveyors, ask if any surveyors have been excluded because they are too “picky”, too “tough” or “are deal killers”. Ask the broker who they would use if they were buying a vessel for themselves.

Comparing surveyors is a simple task. Narrow your list of potential surveyors based on your initial research, and simply request sample survey reports of vessels similar to the one you wish to purchase. Briefing these reports should take no time at all and you will have a good idea which surveyor fits you best, performs the job you require and which surveyor you feel is good.

You should raise any specific concerns you have about the boat or the survey process with the marine surveyor. Mention any problems you have noticed, any deficiencies you have heard about and discuss any specific inspection techniques that you hope to be accomplished. Ask the surveyor about the extent of the operation of the systems they will perform during the inspection process. Many surveyors operate very little equipment; their sample surveys should reveal these details.

Don’t hire a surveyor by price. Price is not likely to vary by any significant amount and the price of the survey is insignificant compared to the cost of the vessel and the potential cost of not hiring a good marine surveyor.

Assure that the marine surveyor’s report will be accepted by the lending institution, insurance company and marina of your choice. This step can be tricky because you may not have made your choice(s) at the time of purchase. An easy vetting process for this purpose is to choose a surveyor who is a member of a recognized surveyor’s association. The Society of Accredited Marine Surveyors (SAMS) and the National Association of Marine Surveyors (NAMS) are well established and recognized by most financial and insurance institutions. Also make sure the surveyor has sufficient length of time in the trade and is experienced with the type of vessel you’re buying.

Don’t skip the survey because you are buying a vessel “as-is”. It is better to know what you are buying than to be surprised. A recent client buying a vessel with no possibility of survey allowances; was happy to learn of two significant survey findings. A bobstay fitting exhibited significant corrosion and a through hull valve was not properly functional. The bobstay fitting was easily removed, cleaned, inspected and reinstalled. A new snubber connection was attached, it was reinstalled with little expense and effort. The through hull valve was subsequently determined to be corroded. The repairer easily broke the valve stem, necessitating the replacement of the valve. The client decided to replace the through hull in conjunction with the valve and thus took the utmost advantage of the haul for survey. Although there was no survey allowance from the seller, the buyer still realized the benefit of a good marine survey.

Don’t accept an old survey done for another client. Get the benefit of the survey process along with the survey. Learn the boat with the surveyor, if you hire a good surveyor, the education during the survey will be invaluable. If you use an old survey, you have no idea of the events of the day and the money and time saved may be the worst investment you ever didn’t make. The report also may not be useful for the finance, insurance or marina requirements.

Brokers desiring long term relationships with boat owners should limit their referral list to good marine surveyors. The true condition of the vessel should be determined and any issues resolved at the time of purchase. This results in a satisfied customer, who feels they were treated fairly and this feeling builds a relationship which is sure to continue. Discard the clutter of negative reputations and you may discover that the “deal killer” is actually a good deal maker. Referring “sub-standard” marine surveyors often comes back to bite brokers. Don’t refer a surveyor that you wouldn’t want surveying your own boat; ethically there should be no difference between a good surveyor when you’re “buying” and a good surveyor when you’re “selling”.

What is a marine surveyor:?

A boat inspector. The most common type of job we do is similar to a home inspector and appraiser combined into one for a boat or a yacht.

What does Christian & Company do?

We basically have two products.

1) We perform “condition and valuation” marine inspections on boats and yachts. These inspections are performed in order to determine “what shape she is in” and “what she is worth”. We inspect the boat, we test virtually every system and component and we encourage sea trials as well. We usually have the boats hauled to allow an inspection of the bottom.

2) We handle insurance claims in San Diego for insurance companies. These insurance inspections determine the cause of loss, identify the scope of damage and review costs.

We also do various special projects, new build monitoring, consultation and litigation support work.

When is a marine surveyor needed?

Our professional boat surveyors in San Diego are typically employed when a boat is purchased (by the buyer), when a boat is refinanced and when an insurance policy is up for renewal. Marine inspections and surveys are also the basis for valuation of a boat as an asset for a multitude of reasons – probate, divorce, etc…

How do you choose a marine surveyor?

Our web site has an article on this, but in short: shop! Ask around, talk with the boat yards, boat brokers, insurance and finance companies and see who is recommended. Boat surveyors in San Diego and around Southern California usually develop a reputation. Often surveyors are known in the industry as a “buyers” surveyor, we suggest the buyer hire a surveyor with a reputation for being thorough and ethical. The client should also make sure the boat surveyor has performed marine inspections and insurance surveys that have been recognized by the insurance and financial institutions being used, as applicable.

What are marine surveyors qualifications?

Qualifications are very diverse among marine surveyors. There is very little organized, formal training. There are no licenses for marine surveyors in most states. All one really needs is a business card. There is no governmental regulation of the industry. There is a school in Florida that runs a six week program. Over the years most boat surveyors in San Diego have learned the business as a trade, from another marine surveyor, more or less as an apprentice. Many banks and insurance companies look for membership in one of two organizations SAMS and NAMS. Members of these organizations need five years surveying experience performing insurance surveys and marine inspections, and must take a test to become accredited members. I have been a member of SAMS since about 1993 and was the Pacific Regional Director for several years.

What type of training and education do marine surveyors have?

Again it is diverse. We require continuing education as part of the membership and a lot of my education has come from symposiums hosted by SAMS. There are many other organizations that provide excellent educational opportunities. They include ABYC, a organization that has developed a set of voluntary standards for boat construction and IBEX, a boating industry educational symposium held once a year.

What are the different types of marine surveyors and surveys?

There are marine surveyors that do what we do, boats and yachts – basically recreational craft. There are marine surveyors that specialize in ships, including the inspection of the ship and cargo inspections. There are also commercial craft boat surveyors in San Diego and around California working on tugs and barges, commercial fishing vessels and special purpose craft, ie. dredges, etc…

What are the criteria for banks and insurance companies?

Membership in either SAMS and NAMS is the most common requirement. Some companies have their own list of accepted boat surveyors. Often companies in San Diego take marine inspections and insurance surveys from anyone if it is complete and the surveyor submits a resume and references. SAMS has produced a “minimum surveyor content list”. It is a good yardstick to measure surveys by.

What types of marine surveys are available?

There are different levels of marine surveys, some are more extensive and some are less. Our San Diego boat inspectors offer a few different types of marine surveys, designed for the needs of the client. Our pre-purchase inspections are very thorough, due to the buying decision that is partially based on the results. We offer a less expensive survey for other purposes, primarily designed for the boat owner who is required to get a survey, but don’t necessarily want one, (for example for insurance renewal or refinancing). For these we offer a discount, but still perform a fairly thorough inspection.

The niche trade of marine surveying has many specialty niches within it. There are marine surveyors who specialize in yachts and small craft, the specialty mostly familiar to the reader of our articles. There are ship surveyors, cargo surveyors, commercial fishing vessel surveyors, tug and barge surveyors and specialty surveyors within these niches. Yacht and small craft surveyors primarily perform two types of surveys, condition and valuation surveys and damage surveys.

Boat owners most commonly require the services of a marine surveyor when they are buying a boat or trying to obtain or renew insurance for their boat. Marine surveyors are the appraisers in the boating industry, and as such are often required for loans, estate issues, divorces and a myriad of other situations where a vessel’s value is required. A growing number of marinas are requiring marine surveys before allowing boats in, as evidenced by the regular calls we receive from boat owners looking to change marinas in the past few years.

So how should you choose a marine surveyor when you need one? Start by understanding what type of survey report you need, its potential uses and make a short list of surveyors able to give you what you need. Remember if you are buying a boat, the survey report may be required by a lender, insurance company and marina. So in addition to finding a marine surveyor who is able to professionally assess the condition of the boat, make sure the survey report will be accepted by the other institutions that may request a copy.

If you don’t have a relationship with a marine surveyor and are trying to develop that short list, consult with your broker (usually they give a list so as not to create any conflict or liability), ask your lender, your insurance agent, the boat yard, the marine manager or your boating neighbors. There are two recognized marine surveying organizations, S.A.M.S., the Society of Accredited Marine Surveyors and N.A.M.S., the National Association of Marine Surveyors. Both maintain online rosters. Other marine surveyors are also great referral sources, your first choice is unavailable, ask them for a referral. Marine surveyors quickly develop a reputations (buyer’s surveyor or broker’s surveyor for instance), and most of the industry professionals are aware of the reputations. If you want a thorough surveyor, ask your broker about their list and if any surveyors are “too thorough” for their list. If you can trust your broker with all aspects of buying a boat, certainly they can be trusted with guidance regarding your choice of a marine surveyor.

After you have a short list, make a few calls; see which surveyor fits your personality. Ask them about their experience, what they do and don’t do and if they will allow or prefer you to attend. The pre-purchase marine surveying event is an excellent opportunity to share knowledge with clients and a great time for the buyer to begin to learn the vessel and its systems. For the truly diligent shopper, review survey reports. The written reports are an excellent way to compare marine surveyors and many surveyors will have sample reports online for easy access. If you need a survey, for insurance or a marina, then use price as another criteria; prices usually don’t vary much and should not be a criteria for choosing a surveyor you want to check out a boat for purchase (penny wise and pound foolish).

If you have a special need, a damaged boat or a unique boat, be sure to explain what you need and ask about the surveyor’s experience with it. Ethically a marine surveyor should decline any job that they are not qualified for, but “the buyer should also beware”.

Once you have chosen the marine surveyor, how can you get the most for your money? If you are buying a boat, we suggest you attend the inspection, spend as much time as you can with the surveyor, be interactive, ask questions and learn. Make sure that everything you care about is tested, try the windlass, all the refrigeration devices, the generator, electronics and through hull valves. Learn how to test that automatic bilge pump and after you buy it, test it occasionally. During the sea trial, take the helm, try the engine controls, auto pilot and change the pre-sets on the multi function electronic display. And then, ponder the water maker…

There are limitations during surveys. The surveyor should discuss the important ones during the survey so you can decide if you need something further. If you want to test everything, including the water maker, make the request before the survey and allow the broker or seller to arrange for anything required. Water makers are often “pickled” (preserved for longer periods of disuse), running them may require special knowledge and the seller may request they be returned to their pre-test state. Most other systems can be tested without prior planning, but you have to take a sea trial to test an autopilot and a surprising few sailors test the spinnaker gear or open all sails.

There are many important parts of a vessel that are difficult or impossible to fully assess. These include the condition of the fuel and integrity of tanks, condition of coring material, battery condition, proper function of tank level gauges, engine instruments, electronics and entertainment devices. Most of these can be assessed to a point but not completely. Many buyers do their homework before a survey, research known weaknesses on boat owner’s group web sites, discuss these issues and the surveyor may bring along a moisture meter, special scope, or other diagnostic tool that may help answer the important questions and reduce your risk. Additional inspections are occasionally necessary, the most common are mechanical surveys on engines, transmissions and generators, and rigging surveys on sailing systems.

After the survey is completed, we feel a thorough “de-brief” is crucial. It is much easier to understand what the survey is reporting if you can see, test, hear, or smell the problem first hand. Some items are removed from the list by including the seller or broker or calling the seller during the “de-brief”. The seller can tell you about the unlabeled circuit breaker that energizes the new chart plotter or the hidden circuit breaker for the windlass.

If you have a damaged boat, the insurance company will often hire a marine surveyor to assist them. In this capacity the insurance company’s surveyor will report on the cause of loss, scope of damage, and cost of repair. The marine surveyor will likely be fair, professional and ethical. There are times when the boat owner should hire their own surveyor. We suggest active communication and involvement during the decision-making portions of damage claims, don’t hesitate to hire your own surveyor should you feel the need, the cost of the surveyor is most often negligible relative to the cost of the repair.

The active boat owner, buyer, and seller will occasionally have other special needs. Marine surveyors are able to assist with project management for new builds or refits. Marine surveyors are used as experts in many types of litigation, including values, repair disputes, salvage issues, and transactional hiccups. We often receive calls from clients to discuss our opinions on normal boating decisions, such as cruising equipment and obscure but common issues, like waste odor. We often are asked for recommendations for service providers, captains, canvas companies, and an unlimited number of other specialties. A marine surveyor often has a wide and unbiased view point that is well suited for this type of assistance. We always welcome these inquiries; good will is integral to good service and we just might need a referral from you tomorrow.

This post was edited on February 24, 2016 at 11:20 AM.